Take samples - but do it right

Flawless sampling - how analysis produces the correct result

When taking samples, a random test is taken from an overall quantity. These samples serve as the basis for the analysis regarding quality assurance. The correct procedure for taking spot samples is therefore a very important subject. Only with representative and authentic samples can reliable information about the quality, properties or composition of a particular material be provided.

Very precise material analyses can be carried out with the most up-to-date technology. However, the technology is no good if an error occurs when the sample is taken and this error continues through all phases of the analysis, with the consequence that the final result of the quality check is wrong.

Correct information about the properties of a material can only be provided if the sample is taken properly and treated in the same way as in the subsequent analysis. The basic point is that the properties and composition of the sample quantity correspond exactly with the material quantity that has to be evaluated.

When taking samples, some essential stipulations such as DIN-standards have to be complied with. The recommendation is to follow a company-internal checklist which should be a fixed component of a company's quality standards. All relevant steps for taking samples are documented in this checklist so that they can be traced at any time.

Location for taking samples

The location from where the samples are taken has to be as clean as possible. At the very least, the use of clean samplers, equipment and tools has to be considered. During the procedure, no external factors must influence the sampling. Even small external contamination can significantly alter the examination result. Detergents which are used to clean the samplers or the sample packaging can also falsify the result of the analysis.

Fachpersonal

Only skilled personnel should take the samples. It must be guaranteed that sampling is carried out exactly in accordance with the stipulated DIN-standards or internal guidelines.

Technical knowledge is of utmost importance because altered circumstances can only be reacted to on-site. Only trained personnel can quickly and safely recognise mistakes that occur or altered circumstances and react accordingly.

Sampling equipment

Choosing the right sampling equipment depends on many different selection criteria. It depends on the material properties of the sampler as well as on the type of sampling, the container or the site where the material is located, and the frequency with which the sampling has to be carried out. In addition to individual requirements for sampling, all equipment should fulfil the basic principles explained below:

Sampler material

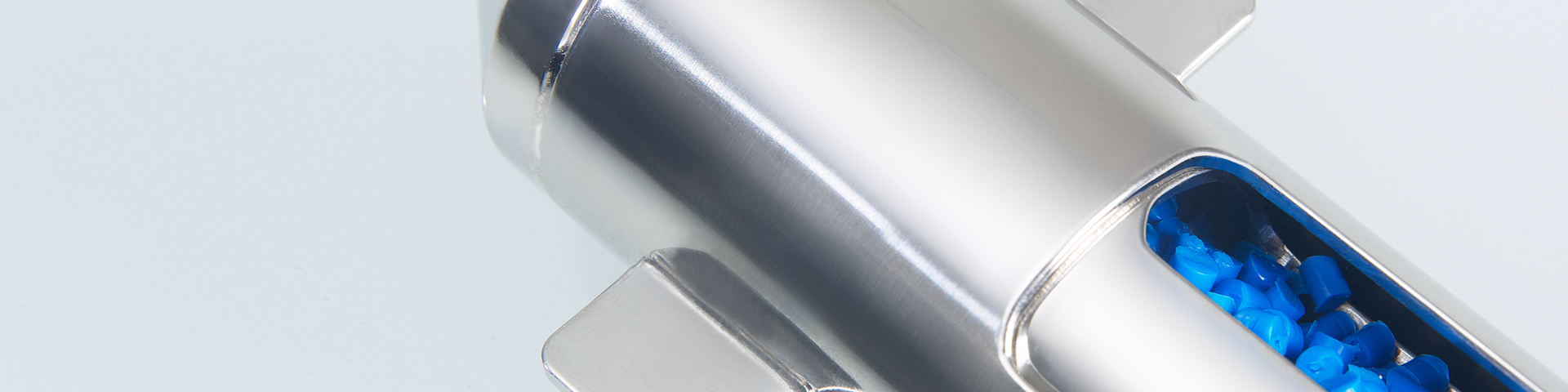

The equipment should be made of inert substances from which no material can come loose and which does not react with other substances and therefore cannot contaminate the sample. The inert substance depends on the medium to be sampled. As a general rule, samplers made of stainless steel and high-quality plastic such as PTFE are very suitable.

Cleaning the sampling equipment

It should be easy and quick to clean the equipment and – under certain conditions – to sterilise it. In the food industry, sterile-packed disposable samplers are recommended which can be disposed of after use.

Processing the samplers

Samplers must not have any grooves or crevices because residual material collects in such crevices and cannot be easily removed. This means that cross-contamination and memory effects can no longer be ruled out.

Surface of the equipment

The samplers' surfaces have to be especially smooth, for example, electro-polished stainless steel or PTFE. This prevents material from being deposited and simplifies cleaning. When selecting the appropriate sampling equipment, you must ensure that it is finished properly on the inside. Equipment with only a smooth external surface will not meet any quality standards.

A distinction is made between physical and analytical/chemical sampling.

During physical sampling, the bulk density, material distribution, material properties and – if required – colouring or contamination are determined. It is especially important in this case that the sampler does not change or destroy the material's properties while taking the sample. A sample taken onsite still has to be transported. During packing and transport, the same high quality standards should apply as during sampling, so that the sample reaches the laboratory unaltered.

During analytical sampling, special attention must be paid to cleanliness in addition to the aspects listed above. However, the material properties can be disregarded at times because the sample will be specially processed. In this case, equipment can be used which changes the physical properties of the material.

Cross-sectional sampling

A sample is taken through all material layers to provide a representative cross-section.

Point sampling

A targeted sample is taken from a pre-determined point. This is done to determine the condition of the material precisely at this point, or several point samples are taken over a larger area or in a large volume container to get an authentic cross-section. All point samples together therefore provide a representative cross-section.

After the sample has been taken, it must be packed for transport. Clean sampling containers connected directly to the sampling equipment are ideal. The sample has no contact with the environment and is packed for transport at the same time. The same conditions that relate to the sampling equipment also apply to packaging, storage, and transport of a sample. Here, too, you must pay attention to the cleanliness of the packaging material and the risk of contamination from loose substances. The sample container is then labelled so that no mix-up can occur and taken to the laboratory – if necessary in coolers. Coolers with temperature monitors in which the ideal cooling temperature is maintained, are recommended.

Advice

If samples are taken from sacks or bags, the insertion points must be closed again afterwards. For this, special labels should be used that stick firmly to dirty surfaces and can be written on.

Any questions?

We will be happy to advise you. Talk to us - telephone +49 7635 82795-0. Or send an email to info@buerkle.de.

Bürkle GmbH - your partner for all questions about manual sampling.