Reusable or disposable samplers?

It depends...

We at Bürkle are often asked about the topic "Disposable and Environment". Because in addition to our large range of reusable samplers, we also carry a wide range of samplers especially for single use. However, whether reusable is better than disposable cannot be answered in general when taking samples. Both have their advantages and disadvantages – these we would like to point out in the following.

Disposable and the environment

Reducing plastic waste

The growing mountain of plastic waste is a global problem that must be solved. An important step is the reduction of disposable products such as straws, plastic cutlery or plastic bags. The first bans have already been adopted. But can disposable products be left out in all areas without any problems? And is the renunciation of plastic products the only solution?

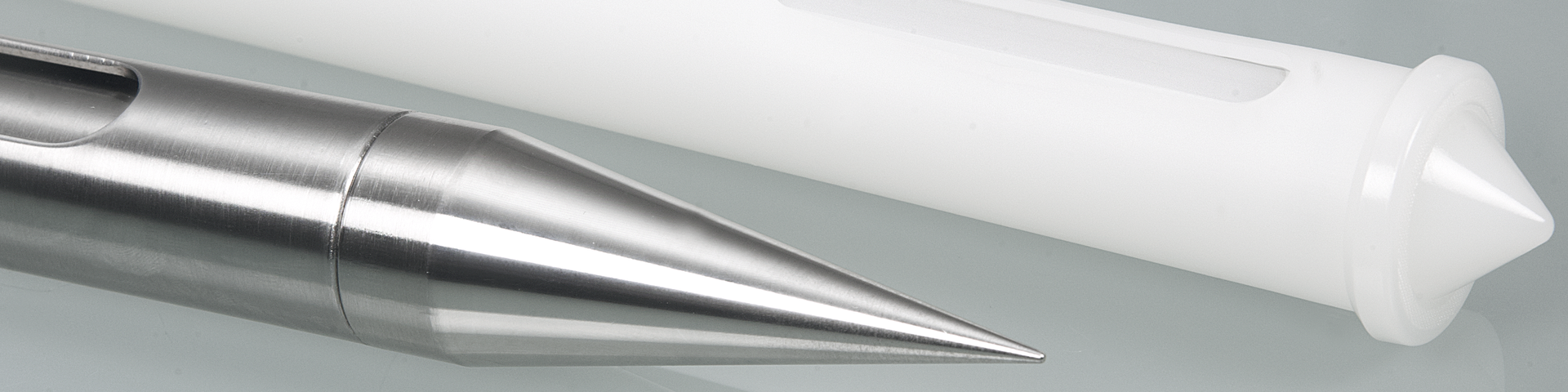

Sterile and particle free during sampling

In the pharmaceutical and chemical industry as well as the food and cosmetics industry there are sensitive areas that require the highest level of purity. This is because the products manufactured in these areas are administered to patients or directly consumed by consumers. Therefore, highest purity must be guaranteed even during sampling. In order to reliably determine the quality of a product, the sample taken must be free of impurities and contamination. For the sampler this means that it must be particle-free and sterile.

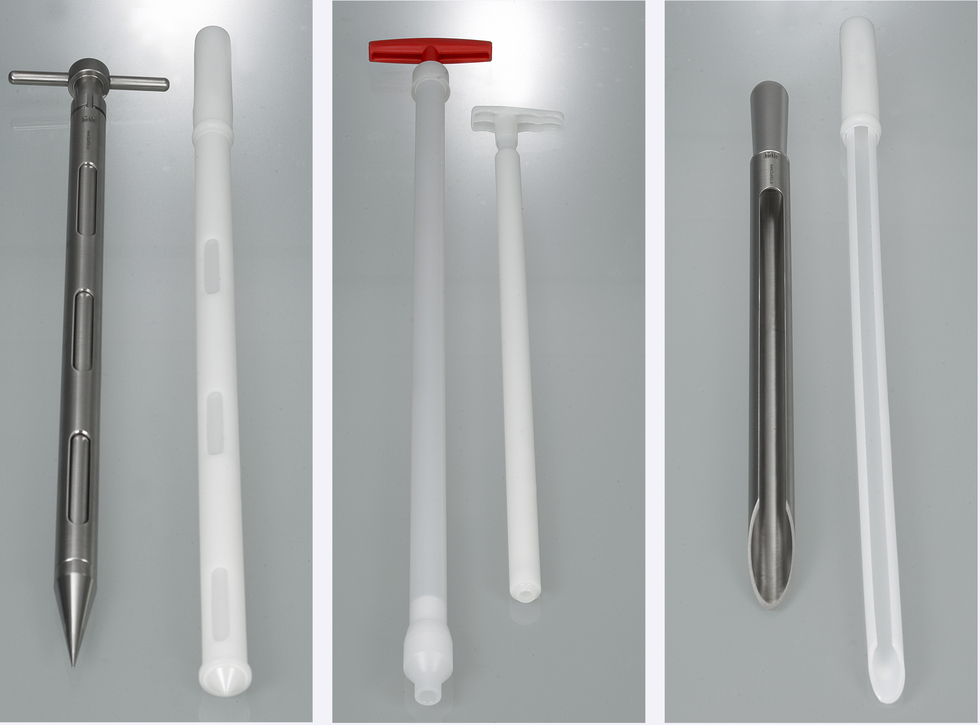

Reusable samplers

Bürkle offers a wide range of samplers for different media and sampling techniques, mostly in both reusable and disposable versions. Both have their advantages and disadvantages: The decisive advantage of reusable samplers is that they can be used again and again. However, this also results in their biggest disadvantage: they have to be cleaned.

At first glance, cleaning seems to be a trivial process. But especially in sensitive industrial areas, quality assurance makes high demands: in addition to the professional cleaning of the sampler, the reproducibility of the cleaning process and proof of its effectiveness are also required. During the audits, the method as well as the exact cleaning procedure must be strictly validated.

Cleaning the sampler

Cleaning can be a complex process: The sampler usually has to be dismounted, cleaned from possible product residues with highly effective and disinfectant cleaning agents before it can be dried and mounted again – this takes a lot of working time and causes high costs for cleaning utensils and cleaning agents.

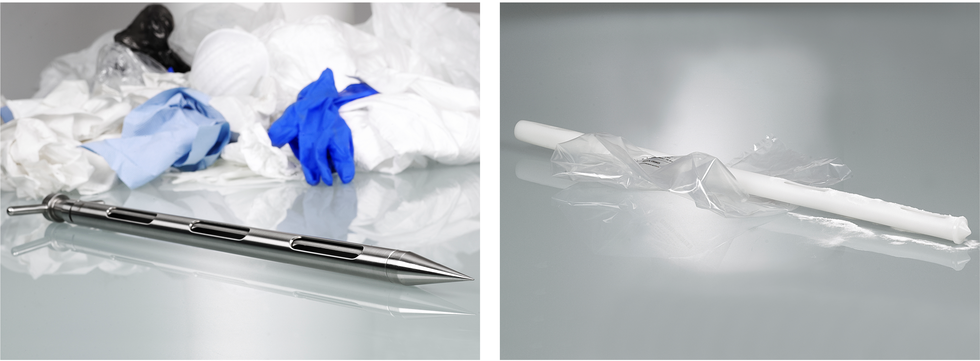

Greasy or strongly adhesive media make cleaning even more difficult, as they can only be removed completely with great effort. Furthermore, sampling of toxic or hazardous media or highly concentrated pharmaceutical ingredients poses a risk to the health of the cleaning worker. Harmful residues can remain in the sampler and endanger the worker. For example, carcinogenic and mutagenic substances, which often cause cancer or can lead to chronic diseases and neurological disorders, pose a great danger to the worker. Therefore protective equipment is required during the entire cleaning process.

Cleaning causes residues and waste

In addition, hazardous and aggressive media cause critical cleaning residues: The contaminated cleaning water must be reprocessed or in some cases even evaporated and the used cleaning utensils (sponges, cloths, brushes etc.) as well as the protective equipment (gloves, apron, face mask etc.) must be cleaned or even disposed of – because disposable products are often used as cleaning utensils and for protective clothing. If the sampler has to be sterilised, costs for the sterilisation bags and the energy required for sterilisation are added. If this process is outsourced to an external supplier, transport costs and packaging materials are also added.

It is clear: The cleaning process of a reusable sampler can be complex and therefore also time and cost intensive. In addition, the cleaning process produces residues and, depending on the application, a considerable amount of waste, which must be treated, cleaned or disposed of. Depending on the application, the mountain of waste or the environmental burden when using a reusable sampler can even be significantly greater than with a disposable sampler.

But even professional cleaning cannot always guarantees the continuous particle-free and sterile condition of reusable samplers. More and more regulations are even ruling out sampling with reusable samplers completely, especially in sensitive areas where the highest degree of purity is required, for example in the production of medicines or food.

But even professional cleaning cannot always guarantees the continuous particle-free and sterile condition of reusable samplers. More and more regulations are even ruling out sampling with reusable samplers completely, especially in sensitive areas where the highest degree of purity is required, for example in the production of medicines or food.

Advantages and disadvantages of disposable

In the sensitive areas of the pharmaceutical, chemical, cosmetic and food industries, disposable samplers are often a good alternative to reusable samplers. Because their most important advantage is that they are continuous particle-free and sterile, which eliminates the risk of contamination during sampling. Their biggest disadvantage: The proper disposal. After all, the reduction of plastic waste is an important step to counteract the further growth of the plastic waste mountain – and this must also be taken into account when disposing of disposable plastic samplers.

Plastic a valuable material?

The problem is not the disposal itself, but the improper handling. Disposing of single-use samplers in dumps is undoubtedly the wrong way. Ideally, they should be returned to the material cycle by recycling. After all, the plastic from which the single-use samplers are made is a valuable material whose reuse helps to protect natural resources.

But if the media to be sampled are dangerous and aggressive, recycling the samplers becomes difficult. Contamination can also become a problem. In many cases, disposal must then be carried out by waste incineration, whereby the waste heat should at least be used to generate energy.

Reusable or disposable – which is better?

There is no general answer to the question of what is the better or even more environmentally friendly alternative. The various advantages and disadvantages of the samplers have made this clear: Reusable samplers can be used over and over again, but in order to ensure continuous particle-free and sterile operation, professional cleaning is required, which in certain cases is very complex. Disposable samplers, on the other hand, are continuously particle-free and often sterile, but here professional disposal must be guaranteed, which is often not easy to implement.

Using disposable products just for convenience is certainly the wrong way. The general rejection of disposable products is also wrong. Every company and every user bears a responsibility for the environment. Therefore, everyone must always ask himself the question what is the optimal solution for the respective application – disposable or reusable?

This is also not about doing without plastic completely – this is simply not realisable for many companies. However, companies must act responsibly and always keep the environment, the consumer and operational concerns in mind. Bürkle supports its customers in choosing the appropriate sampler. Whether disposable or reusable is the right solution for your application – ask us, we will be pleased to help you.

Product lines LaboPlast® Bio and SteriPlast® Bio

In order to consider an ecologically sustainable action, Bürkle also offers disposable samplers that are made of bio-plastic. Only plastics made of renewable resources are used for the production of these. The bio-plastic is 100 percent recyclable and does not contain any fossil raw materials. This means a significant saving of CO2 and a reduction of the greenhouse effect.

The bio-polyethylene used for the disposable samplers is made from bio-ethanol, which in turn is obtained from the renewable raw material sugarcane. The common polyethylene, on the other hand, is obtained from fossil raw materials such as oil or natural gas. CO2 is already bound from the atmosphere during the production of the bio-plastic. Each ton of bio-polyethylene absorbs more than two tons of CO2 from the atmosphere – that supports the reduction of greenhouse gases. At the same time, the bio-polyethylene has the same properties as "conventional" polyethylene made from fossil raw materials: It is just as versatile and can also be recycled.

In addition, the samplers are also manufactured, assembled, packaged in clean room and optionally sterilised by gamma rays. The LaboPlast® Bio and SteriPlast® Bio samplers meet the same requirements as disposable samplers made of conventional plastic. Even the individual packaging is mostly made of bio-polyethylene, which guarantees a product that is as sustainable as possible.

Thus, the LaboPlast® Bio and SteriPlast® Bio samplers from Bürkle represent the best possible disposable alternative to the reusable samplers that are of course also available.